All Categories

Retaining Compound Green 620 Sleeve Retainer High Strength Cylindrical Metal Components Assemblies Locking and Sealing Anaerobic Glue Prevent Loosening Abrasion 1.69 Oz/50 ml (620)

Share Tweet

Get it between 2024-05-14 to 2024-05-21. Additional 3 business days for provincial shipping.

*Price and Stocks may change without prior notice

*Packaging of actual item may differ from photo shown

- Electrical items MAY be 110 volts.

- 7 Day Return Policy

- All products are genuine and original

- Cash On Delivery/Cash Upon Pickup Available

Retaining Compound Green 620 Sleeve Retainer High Features

-

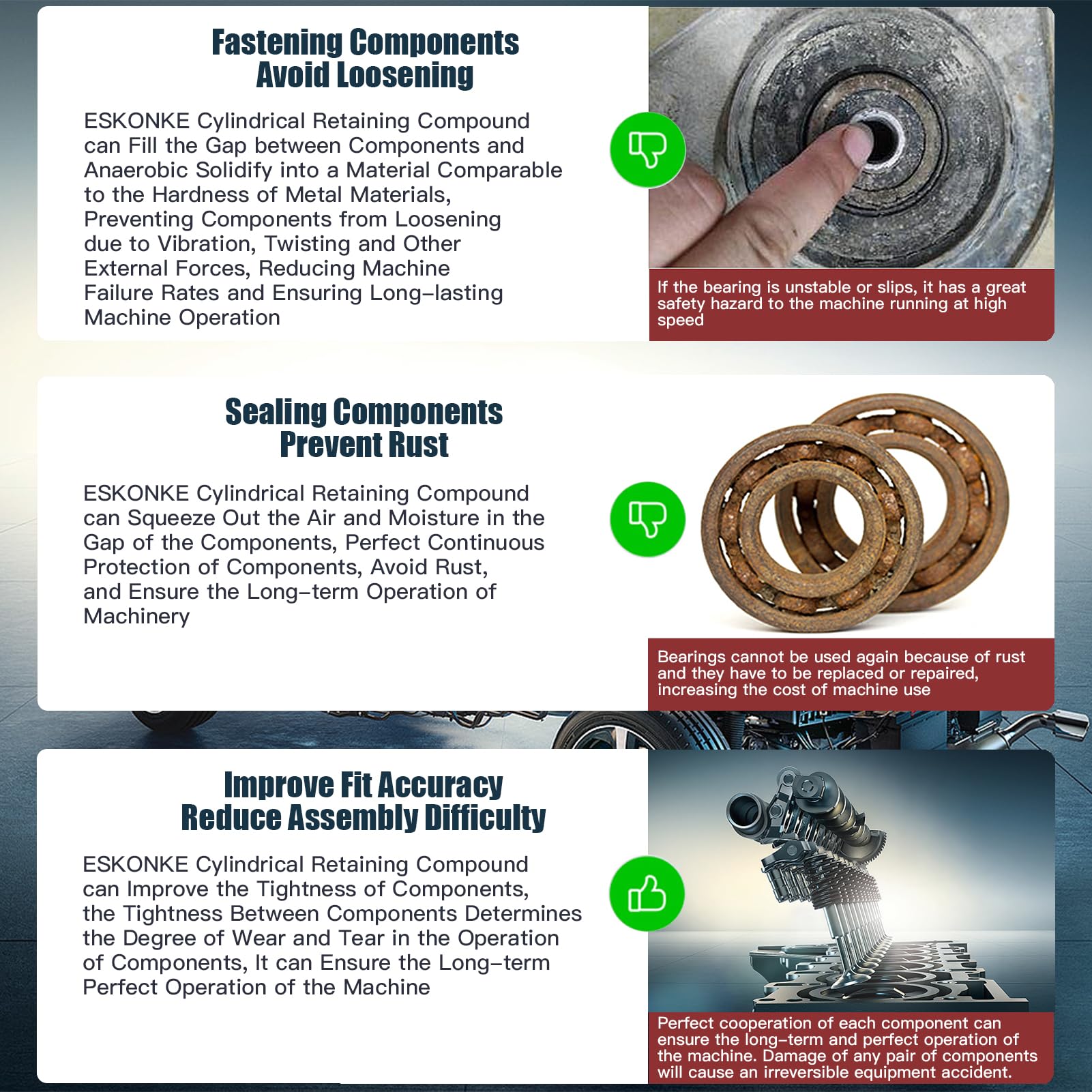

Ideal glue for the installation of smooth/unthreaded cylindrical metal assemblies: 1,Fill the voids and reduce the precision requirements of design, production and installation; 2,Prevent assembly from loosening, wear and corrosion; 3,Evenly distribute loads and stresses during assembly; 4,Sealed from oxygen and other contaminants. Extend the life and safe use of the equipment!

-

High Strength: After complete curing, Shear strength can be comparable to that of metal materials (609 ≈ Aluminum, 620 & 680 ≈ Copper, 603 & 638 ≈ %0.1 C Steel, 648 ≈ %0.2 C Steel), Ensuring efficient and stable operation of the equipment. Needs to be heated to 250 ℃/482℉ when disassembling, and mechanical auxiliary equipment is required.

-

Applicable Scope: Suitable for the assembly of any smooth, unthreaded cylindrical metal components, Such as keys and shafts, bearing, rotor shaft, bushing, casing, cylinder liner, key slot, valve sleeve, movement sleeve, valve bushing etc. Choose the appropriate use according to the characteristics of different models.

-

Applicable Material: Suitable for all kinds of solid metals, even metals with active surfaces such as iron, copper, brass, steel, etc. not to mention metals with inert surfaces such as stainless steel, aluminum, gold, etc.

-

Simple Use: Just apply the product evenly to the fixed location, the product will start curing within 60 minutes after the assembly is installed, and it can be used normally after 24 hours of standing.

-

Function: Fill gaps between components / Lock components to prevent loosening / Prevent component abrasion & corrosion / Improve the accuracy of component fit / Isolate oxygen and prolong product life / Tightness to prevent leakage / Evenly distribute loads and stresses / Repair minor defects in parts / Reduce design and process complexity

About Retaining Compound Green 620 Sleeve Retainer High

Net Liquid Content:1.69 fl oz Bottle Capacity:3.4 fl oz Suitable for retain valve sleeves, injection molding core sleeves, valve sleeves, cylinder liners, keyways, etc., prevent metal micro-shock wear and corrosion, and seal to prevent leakage Function Fill gaps between components Lock components to prevent loosening Prevent component abrasion & corrosion Improve the accuracy of component fit Isolate oxygen and prolong product life Tightness to prevent leakage Evenly distribute loads and stresses Repair minor defects in parts Reduce design and process complexity Precautions 1, Curing conditions: metal material; air isolation; Gap is lower than the maximum gap; 2, Make sure the components are at room temperature, dry and clean. The cleaning solvent can use trichloroethane, trichloroethylene, methyl ethyl ketone, methanol, etc. 3, Grinding the metal surface that needs to be bonded is beneficial to improve the bonding strength; 4, Not suitable for use in pure oxygen or oxygen-enriched environments; 5, Not suitable for bonding porous materials such as plastic, wood, paper, etc; 6, When dismantling, it can cooperate with mechanical auxiliary equipment and heat the components to 392~572°F, 7, Seal as soon as possible after use to avoid volatilization of active ingredients; 8, Do not pour the unused glue back to avoid contamination; 9, Do not replace the storage container during storage; 10, Store in cool place(46~70°F), avoid sunlight.